Let’s get something straight. Soft-shell crabs are not a variety of crab. They’re not a particular species but just regular crabs that have gotten too big for their shells and thus, need to maneuver out of them in order to continue growing.

They wriggle out of their exoskeletons by first cracking their backs between the carapace and the abdomen before gently crawling out. This phase takes hours but to create an inner soft shell takes just minutes—around 20 to be exact. The crabs’ bodies swell with water to form new armor. At that critical point, they are in such a delicate state and so vulnerable to cannibalization from other crabs that they must transition into hiding, behind a rock or in the sand. It is during this process, this small window of time, that they must be seized and harvested, before the new shell hardens and becomes too hard to chew. That’s also when they become soft-shell crabs.

Crabs molt multiple times throughout their lifetimes. Much of their body growth happens while they are young and small, about the size of a matchbox, and less frequently when they reach approximately 200 grams. Their skeletons are discarded, sometimes used as animal feed. The soft-shell crabs, on the other hand, are immediately placed in a basin of freshwater, mixed with a bit of chlorine for disinfection and sanitation, before being washed again. They are then frozen for easy handling (packing them alive increases chances of losing limbs) then packed, chilled, or frozen while in storage, then sold to customers.

Planting projects

Roger Jude Garcia and Sarex Gameng have been cultivating soft-shell crabs for two years now, thanks to the Tuason Development Foundation, Inc., (TDFI) in partnership with the USAid. “The idea of the foundation is not to dole out but to empower communities so that they can transform their lives. It’s a shared responsibility,” says TDFI president Rosanna Tuason-Forés.

“Our objective is to provide sustainability through the projects and also to combat poverty,” adds Ian Fernandez, program manager of Davao Gulf Business Innovator, a project of TDFI. Every year, they conduct talks in various barangays around the gulf to make people aware of the business opportunity program they are offering. Those interested would have to submit assessment forms and proposals from which the team chooses the most promising projects.

The selected entrepreneurs then go through workshops and even a mall showcase, which determines if their products have market appeal. If they pass these, then they receive grants as well as loads of help from the TDFI—from business registration and government compliance to production and marketing, and coaching and mentoring—more than enough to run and sustain their new business.

Manual labor

Garcia and Gameng applied for it and fortunately, their proposal got accepted. “Napakaganda ng programa kasi nandiyan talaga ang support. May kasamang training pa,” says Garcia. “Kailangan lang talaga pagsikapan ng grantees.”

And that’s exactly what the duo has been doing, with Gameng handling the financial operations of the business, and Garcia—armed with inland fishery training from the Iloilo State College of Fisheries—taking care of the technical stuff.

Together, they began with a 500 square-meter area of brackish water in Brgy. Liboganon, Tagum City, Davao and 500 crablets back in 2014. There are four species of mud crabs and of the lot, they work mostly with the Scylla olivacea or the native/orange mud crab; on occasion, although very rare, they work with king crab too.

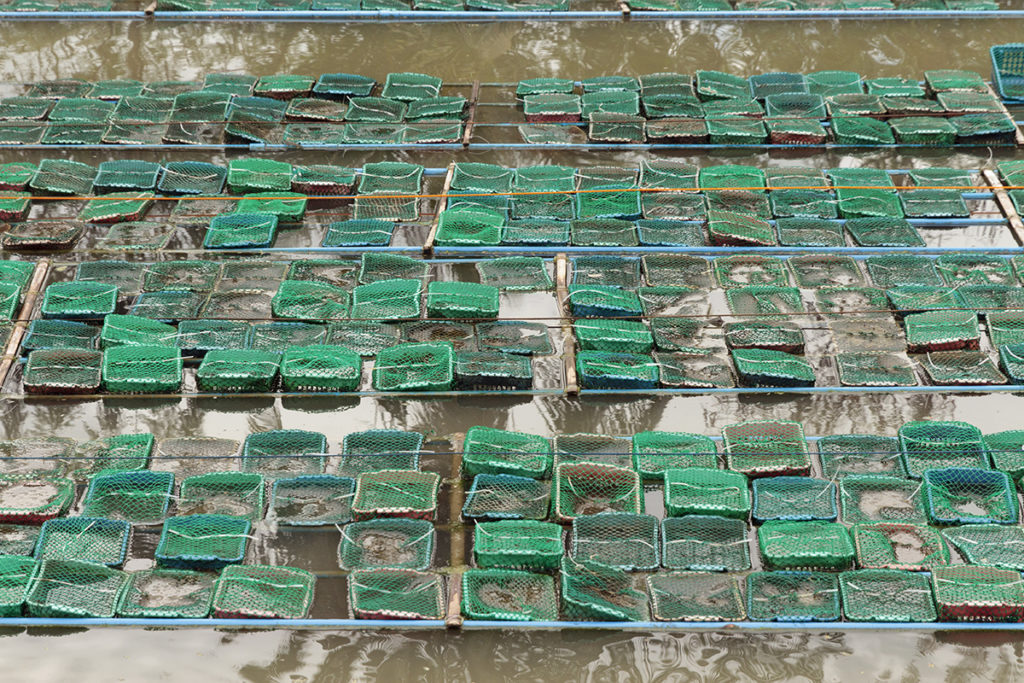

Each crablet is housed in a perforated tray that has been sown with a net on top to prevent escape. They are then submerged in the pond, forming a row to maximize space and for ease of management. The next day, they are fed chopped cow’s liver purchased from the slaughterhouse or kuhol.

Their days are pretty routine. People bring over their catch of crablets for the day, from which Garcia and Gameng select and purchase the good quality ones. Sometimes, as the suppliers have no mode of transportation, they are forced to travel and pick them up themselves. They make sure they are of the right size—too small and the farm operators believe that they are deprived of their life cycle, too big and they molt less and have a tendency to be tougher.

Each crablet is housed in a perforated tray that has been sown with a net on top to prevent escape. They are then submerged in the pond, forming a row to maximize space and for ease of management. The next day, they are fed chopped cow’s liver purchased from the slaughterhouse or kuhol. Land farmers are more than happy to dispose of it. Trash or rough fish can also be used, but Garcia and Gameng believe that this may disrupt the balance in ecology.

Then begins the careful monitoring of the crablets. With a hook in hand, they check the trays one-by-one to see if the molting process has begun. There is no scientific study yet to indicate when a crab is about to shed its shell, thus the manual checking; though tedious and time-consuming, remains the most effective method. Ideally, this should be done every four hours. But Garcia and Gameng sometimes do only two to three spot checks based on sheer gut feel.

On a lucky day, they get to harvest one kilo of soft-shell crabs. But slow days often provide three to none. They sell them for a farm gate price of P700 a kilo and since their business is still small in scale, they supply to a limited client base.

A good catch

The business of soft-shell crabs is a promising one. Garcia says there are only a handful of people doing it right now, but those who see its potential are quick to join the bandwagon.

For one, the model is easy to copy and adopt. People can raise and harvest soft-shell crabs on their own given the proper supplies and a pond that doesn’t even have to be that deep. And since crabs naturally grow out of their shells and pick no particular season, farmers are guaranteed to have products any time of the year.

Ponds propagating bangus, for instance, can accommodate the crab trays and share space without affecting the farming for each. This way, the use of the pond is maximized and the sales increase.

The business also helps communities. In the case of Garcia, he employs kids who are not doing anything and want to earn extra bucks to sew the nets that cover the trays for three pesos. A peso is given as payment for those that need minor repairs. Those who happen to catch crablets can also sell them to those who raise them. Just a bit of elbow grease and the people can earn enough for a decent meal.

In addition, the people who want to get into the cultivation of soft-shell crabs do not need to convert their fisheries entirely but just add to what they’re currently operating with. Ponds propagating bangus, for instance, can accommodate the crab trays and share space without affecting the farming for each. This way, the use of the pond is maximized and the sales increase.

Bred to last

Although not a dire need, the facility’s need to check each tray faster and more efficiently is something that is still a plan waiting to be turned into actuality. A group of master’s students from Stanford proposed a ramp that will enable the farmer to see the content of each tray in no time. But it can only be a hope and wish for now as Garcia and Gameng try to stabilize their business to earn enough to pay for the proper equipment.

Another challenge that gravely affects them is the constant supply of crablets. Rather than using them for soft-shell crabs, the suppliers would rather stock them in their own ponds and grow them big so that come December, when there’s client demand, they can sell them as regular crabs and gain more profit from them.

Lastly, crablet suppliers in their area often request Garcia and Gameng to pay them first before they deliver their order of crablets. To do so, the farm operators need a revolving fund to go around and make the system work for the business.

Garcia sees only one solution to solve many of their challenges—a hatchery. Having a facility that will breed the crablets for them will guarantee constant supply that will consequently allow them to utilize every square inch of the pond space for their soft-shell crabs.

Originally published in F&B Report Vol. 14 No. 1

Hi! Can I get your contact number? Im from Palawan and Im running 2 restaurants here